Material Information

The objective was to benchmark the performance of the novel fuel cell materials that I created, with a focus on electrical resistivity. A review of the prior-art revealed that everyone was using substandard methods given the influence of material anisotropy. Consequently, I developed superior methods and hardware to measure three-dimensional transport layer resistivity as a function of mechanical strain.

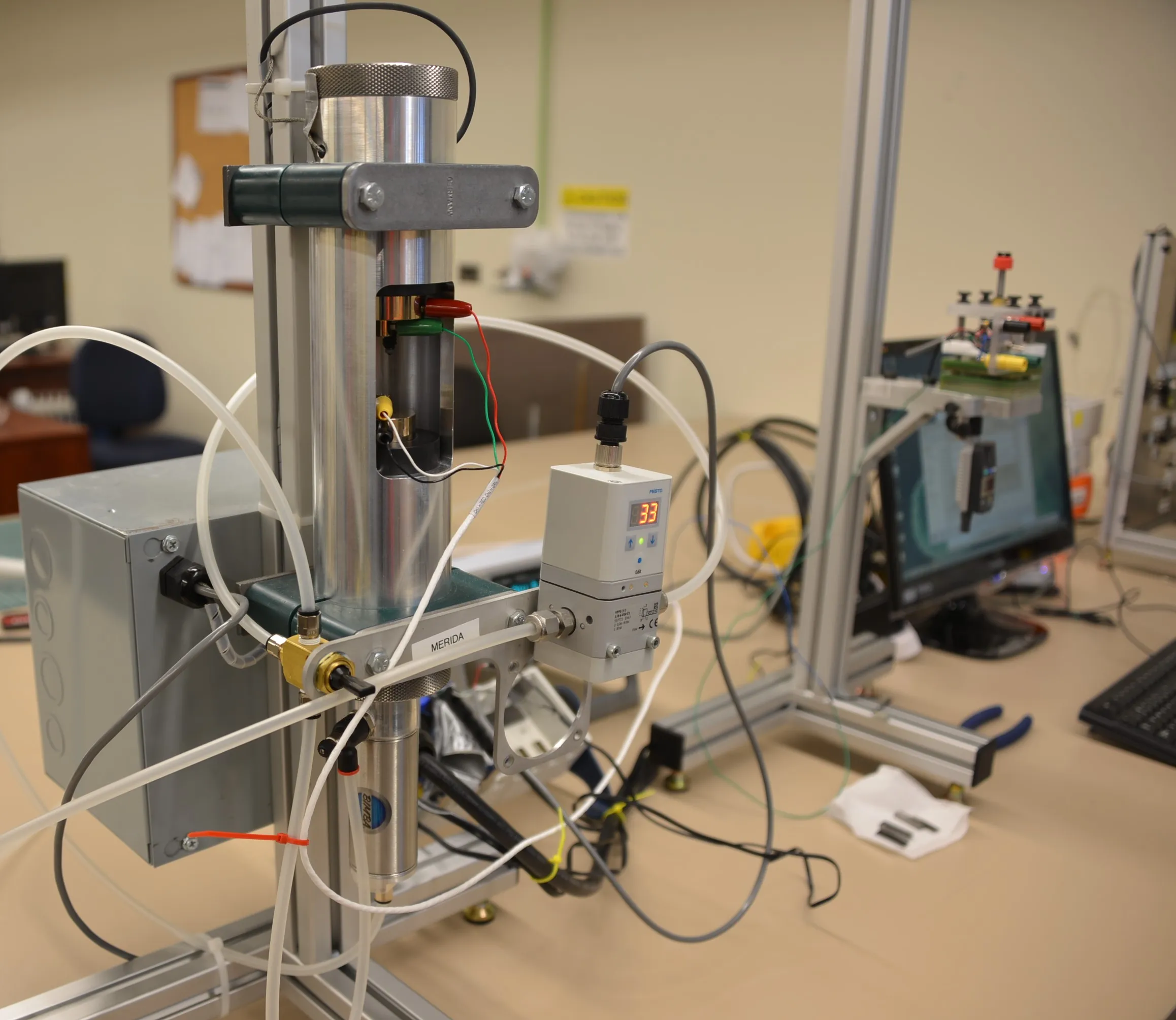

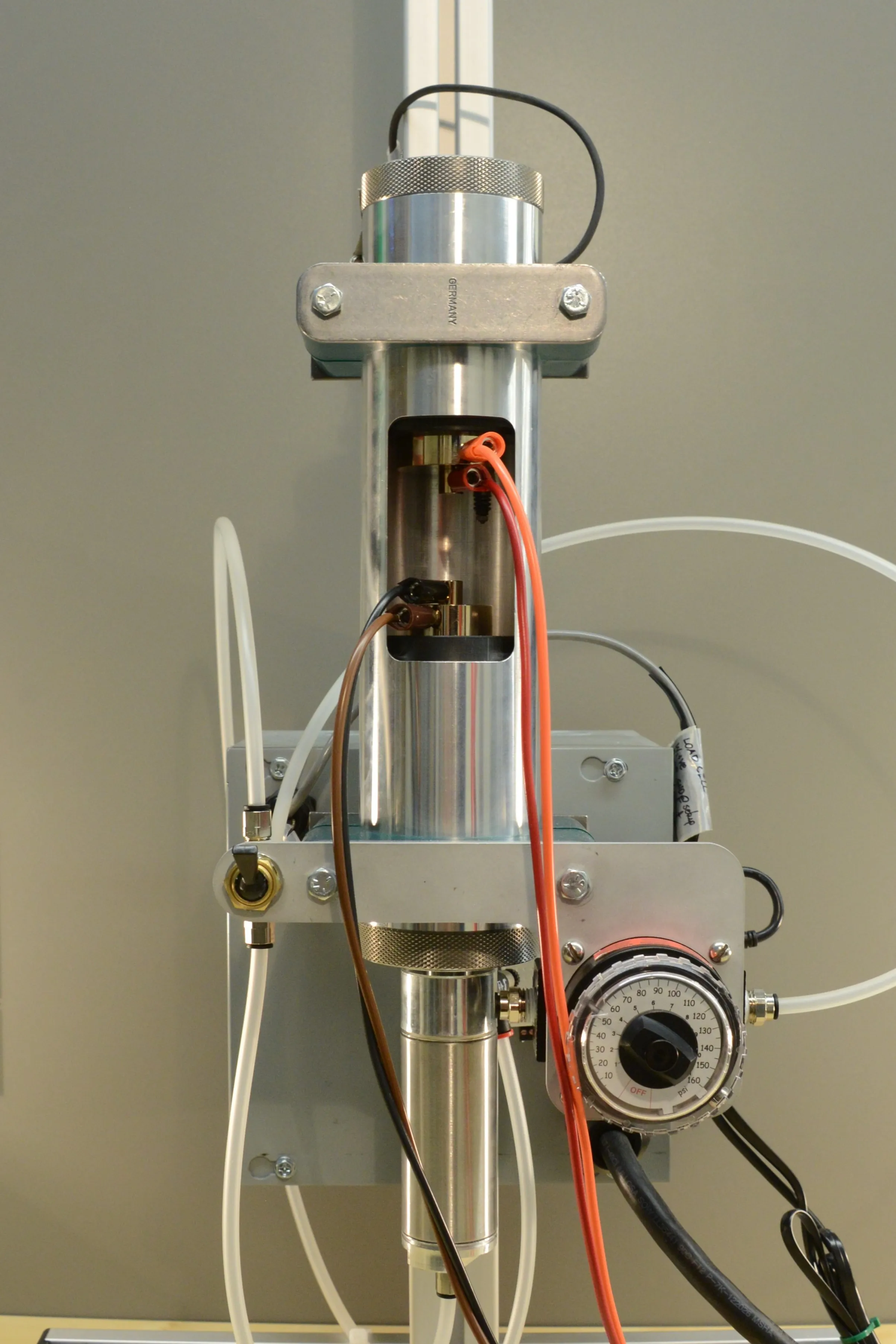

The through-plane device featured gold-plated anvils which are pneumatically driven to compress a sample. Instrumentation comprised: force via a load cell; displacement via an LVDT; electrical resistance via high-resolution ohmmeter; and force control via a digital regulator (later addition). An National Instruments DAQ and LabVIEW program were used to automate testing. The operator only needs to load/unload samples and hit go.

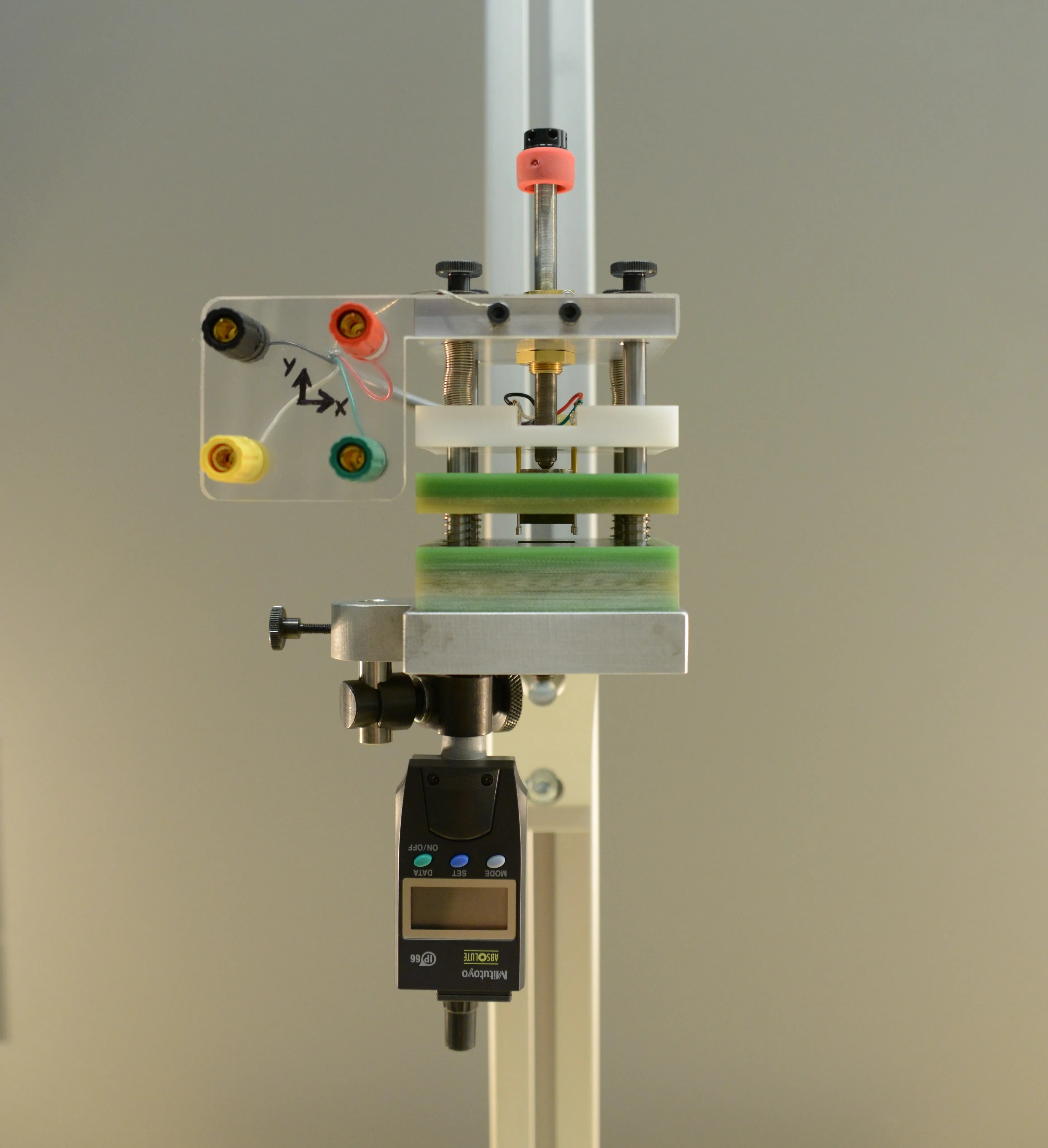

The in-plane device featured a square array of probes for resistivity sensing, and a screw-driven non-conductive anvil to apply mechanical strain (logged via a digital indicator). A high-resolution ohmmeter coupled to an National Instruments DAQ running LabVIEW was used for logging resistivity. The operator loads/unloads samples, and is guided by the program through the semi-automated testing procedure.

Aside, as part of the larger suite of ex-situ material testing capabilities, I also designed and built a through-plane gas permeability apparatus.

My novel approach to measuring electrical resistivity was published in peer-reviewed literature. The system also provided quantitative evidence of my novel material synthesis method’s ability to control morphology. World leading capabilities were developed, and were subsequently contracted out to local fuel cell industry.

More information about this work is available here and here.